Aerospace in 3D Printing: A new way to fabricate aerospace parts

Join industry leaders by investing in additive

A new way to fabricate efficient and sustainable composite and metal parts

Aerospace industry leaders are swiftly adapting to evolving supply chains and labor demands through Aerospace 3D printing, from on-demand MRO and spare parts in commercial aviation to innovative advancements in Urban Air Mobility. The Digital Forge by Markforged provides a reliable way for manufacturers to create using familiar materials through Aerospace 3D printing, enabling the unattended, overnight fabrication of end-use carbon fiber composites. This Aerospace 3D printing technology eliminates multi-week lead times and expedites fees for metal and composite prototypes, tools, and fixtures. Markforged has now introduced ULTEM™ 9085 Filament on the Digital Forge, reinforced with continuous Carbon Fiber through the FX20 3D printer for aerospace-ready composite strength. Additionally, Onyx FR-A and Carbon Fiber FR-A offer traceable, flight-ready, flame-retardant printing solutions through Aerospace 3D printing. *ULTEM™ and 9085 are trademarks used under license from SABIC, its affiliates, or subsidiaries.

Traceable, Purpose-Built Materials

ULTEM™ 9085 Filament, Onyx FR-A, and Carbon Fiber FR-A are all lot-qualified, flame-retardant materials designed specifically for the aerospace, transportation, and automotive industries. These materials are purpose-built for Aerospace 3D printing, ensuring lot-level material traceability and passing the stringent test suite required for qualification under 14 CFR 25.853 for most 3D-printable parts. Onyx FR-A and Carbon Fiber FR-A, when printed using Aerospace 3D printing on the Markforged X7, are currently undergoing qualification through the NCAMP process. These advancements in Aerospace 3D printing highlight the commitment to meeting industry-specific requirements and enhancing performance standards.

Prepared for Regulated Applications

Markforged recognizes the advanced regulatory and functional requirements of the aerospace industry. Through Aerospace 3D printing, they offer traceable materials, software version-locking for parts, and Blacksmith in-process laser inspection. Additionally, the ongoing NCAMP qualification for Onyx FR-A and Carbon Fiber FR-A on the X7 underscores their commitment to meeting these standards. These elements of Aerospace 3D printing provide the foundations for accelerating the path from digital art to flying parts, ensuring compliance and reliability at every step.

On-Demand, Distributed Manufacturing

Turn the supply chain into a competitive advantage with Aerospace 3D printing and distributed manufacturing at bases, airports, and maintenance depots. With a digital library and on-demand fabrication, you can get MRO and spare parts where and when you need them through Aerospace 3D printing, the only additive manufacturing platform built to go anywhere. This capability ensures that critical components are always available, streamlining operations and reducing downtime with the flexibility and efficiency of Aerospace 3D printing.

ULTEM™ 9085 A Aerospace Ready 3d printing material

Long used as a high-value aerospace polymer, ULTEM™ 9085 Filament is now printable using Aerospace 3D printing on the FX20. Its superior performance in flame, smoke, and toxicity (FST) tests, coupled with its high strength, makes it a chosen material for both aircraft and spacecraft. The FX20 is Markforged’s new flagship 3D printer, capable of reinforcing ULTEM™ 9085 Filament with continuous Carbon Fiber through Aerospace 3D printing. This advancement ensures that the aerospace industry can leverage the benefits of Aerospace 3D printing to create robust and reliable components.

High-Performance Materials

Utilize Markforged's ever-expanding portfolio of metals and high-performance composites to 3D print high-fidelity parts capable of withstanding the extreme environments common to flying vehicles.

Built for Aerospace Requirements

Markforged recognizes the advanced regulatory and functional requirements of the aerospace industry. Markforged is one of only a few companies to offer a UL94 V-0 Rated FFF printing material.

Distributed Manufacturing

Turn the supply chain into a competitive advantage with distributed manufacturing at bases, airports, and maintenance depots. Get parts where and when you need them with Markforged's digital parts platform built to go anywhere.

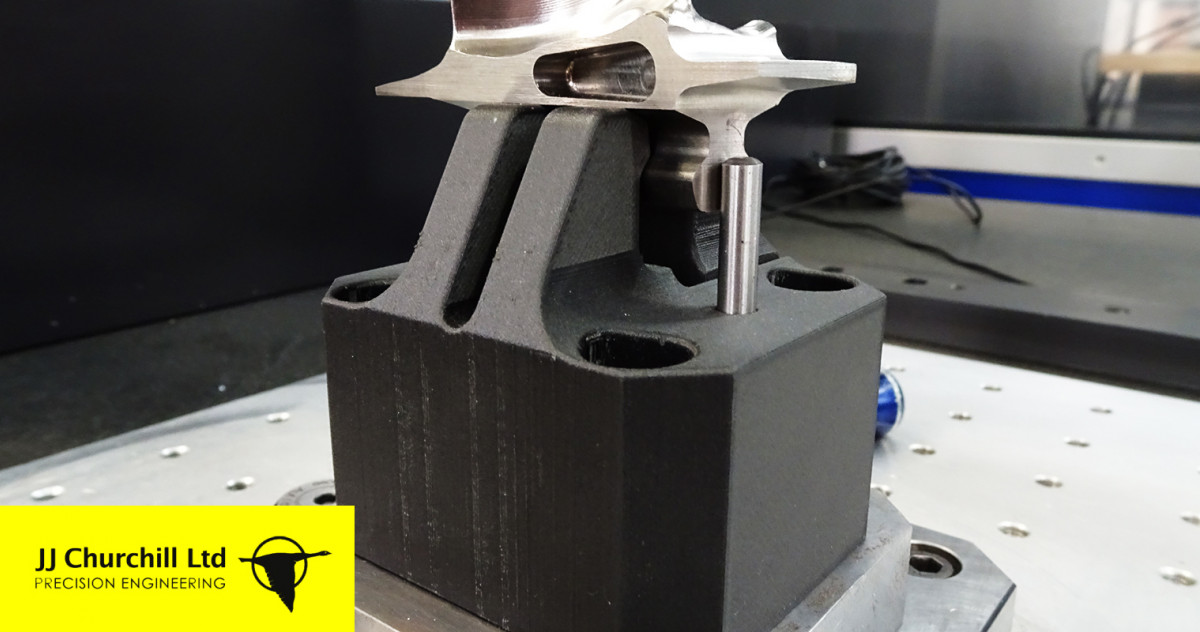

JJ Churchill: CMM Inspection Fixture

JJ Churchill trusts the precision and unmatched strength of Markforged's fiber- reinforced Onyx material. Find out how JJC and over 100+ of the world's top manufacturers use the Markforged platform to dream bigger and accomplish more.

Read moreTalk To An Expert

Our team of Application Engineers and industry experts at Chemtron are here to help. We can answer any questions you have, ranging from details about Markforged material properties to building an additive transformation roadmap for your business.

"once we realized the directional strength properties available with the Markforged products, we haven't used anything else"

Contact Us

Our team of Application Engineers and industry experts at Chemtron are here to

help. We can answer any questions you have, ranging from details about Markforged material

properties to building an additive transformation roadmap for your business.

Get in touch with Chemtron today!

203A Henderson Road,

#02-03 Henderson Industrial Park,

Singapore, 159546

Phone: +65-62737252

Email: info@chemtron.com.sg