Manufacturing at the Tactical Edge: The Future of Military Drone Operations

Explore how tactical edge manufacturing and 3D printing are transforming military drone operations with faster production, advanced materials, and field-ready solutions.

Read MoreScaling UAV Manufacturing with 3D Printed Drone Parts

Discover how 3D printed drone parts accelerate UAV development, reducing lead times while improving strength, repeatability, and control over proprietary designs.

Read MoreAutomotive Additive Manufacturing in High-End Fabrication

Discover how automotive additive manufacturing accelerates high-end fabrication, reducing lead times while improving precision, repeatability, and performance.

Read MoreTransforming Aviation MRO with 3D-Printed Aircraft Components

Discover how 3D printing and CFR materials are transforming aviation MRO with faster, certified aircraft components, reduced downtime, and efficient interior upgrades.

Read MoreHow Markforged Helps Canon Build Precision Tools Faster & Smarter

Discover how Canon cut costs, reduced lead times, and improved precision by using Markforged 3D printing to create tools, jigs, and fixtures in-house.

Read MoreHow Markforged 3D Printing Helps Tsalla Aerospace Build Stronger, Smarter UAVs

Discover how Markforged 3D printing helps Tsalla Aerospace build stronger UAVs faster with seamless parts, lower costs, and improved performance.

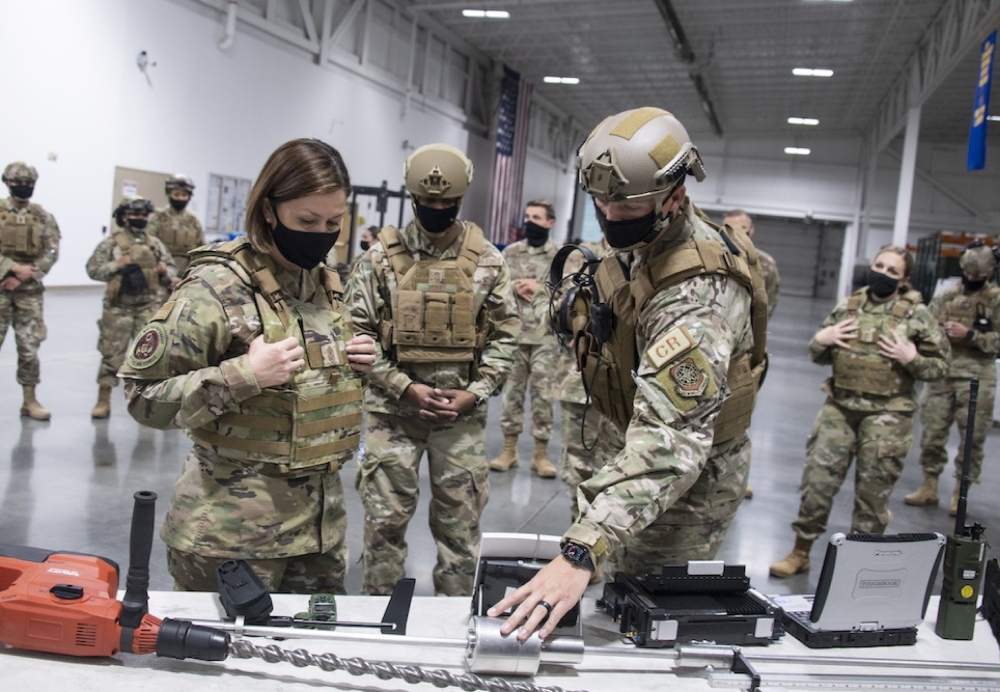

Read MoreHow 3D Printing is Transforming Defense Readiness Across Military Branches

Discover how 3D printing boosts U.S. Army, Navy, Air Force & Marines readiness with on-demand parts, lower costs, and faster mission support.

Read MoreBoosting Efficiency for Packaging Machine Builders with Custom 3D Printing Solutions

Discover how custom 3D printing helps packaging machine builders cut costs, speed up production, and deliver flexible, high-performance solutions.

Read MoreThe Evolution of Metal Parts Manufacturing: A Factory Floor Perspective

See how metal parts manufacturing evolved from casting to 3D printing for faster, flexible production.

Read MoreFood Safe 3D Printer Filament: What It Means and Why It Matters

Discover how food-safe 3D printer filament keeps production fast, flexible, and compliant in food manufacturing. Safety meets innovation.

Read MoreCase Study: GriPalm's High-Performance Robot Gripper

GriPalm's 1,055g gripper lifts 20kg with durability. Boost efficiency with Chemtron Pte Ltd's advanced automation solutions. Contact us today!

Read MoreCashco Boosts Efficiency with Markforged 3D Printing

Discover how Cashco reduced tooling work by 90% and boosted efficiency with Markforged 3D printing, achieving ROI in just 3 months.

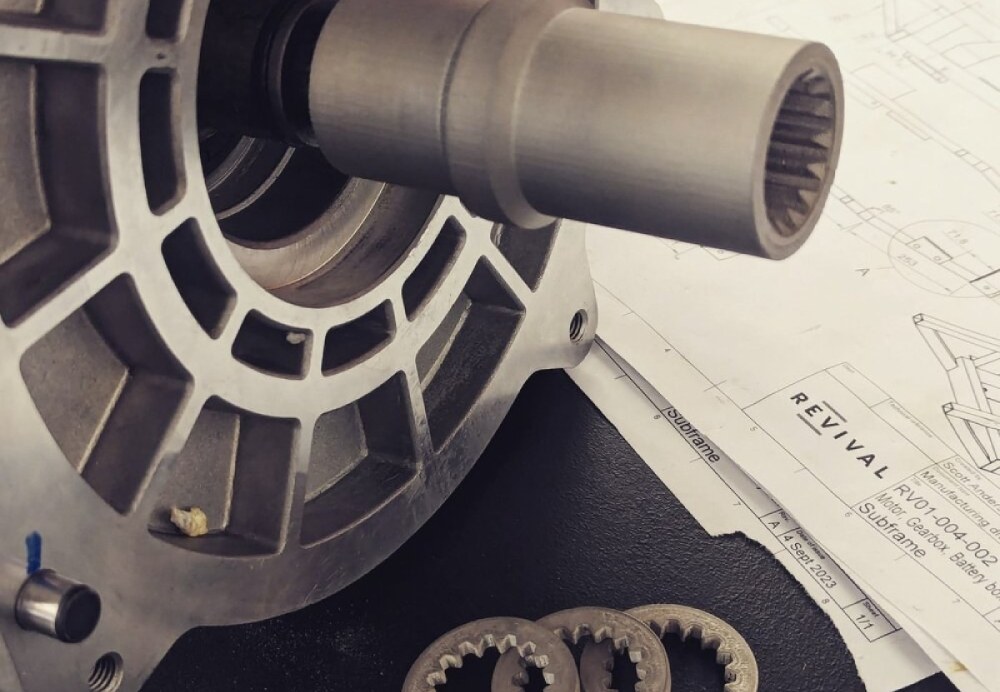

Read MoreRevival Electric Vehicles: Pioneering Classic Car Electrification

Discover how Revival Electric Vehicles used Markforged 3D printing to create durable, cost-effective stainless steel spline adapters for EV conversions.

Read MoreHow McService Enhances Efficiency with the FX20™ 3D Printer

Discover how McService uses the FX20™ 3D printer to cut costs, save time, and enhance efficiency in industrial automation. Explore the benefits today!

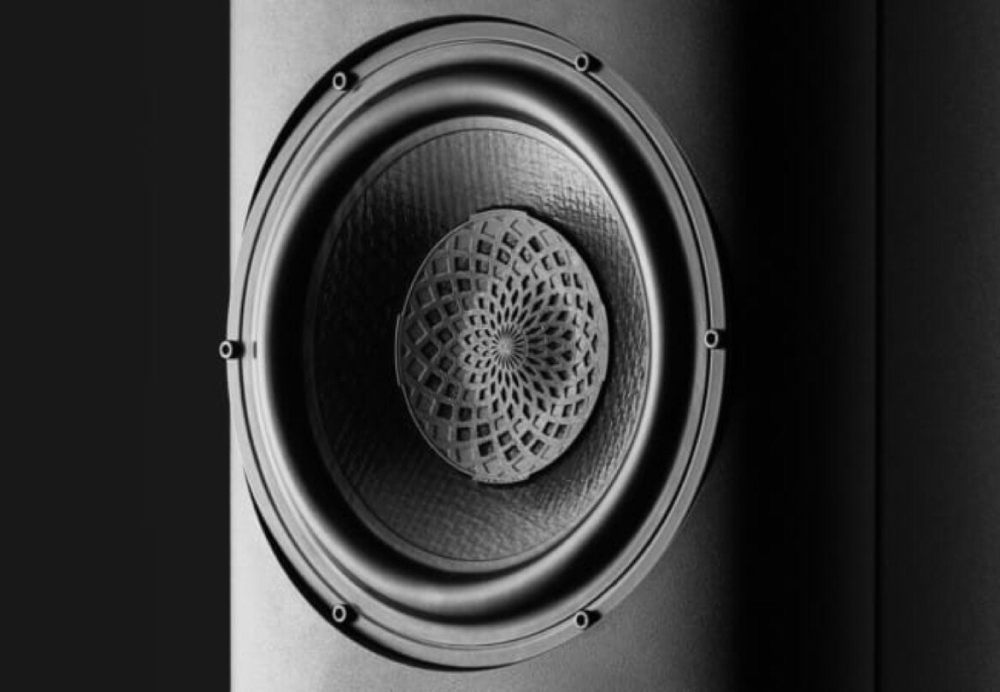

Read MoreRevolutionizing Vinyl Playback: Wilson Benesch's Innovation Journey

Explore Wilson Benesch's journey in vinyl innovation, blending carbon fiber design and advanced 3D printing to set new standards in high-tech audio.

Read MoreVestas: Pioneering Wind Energy with 3D Printing Solutions

Discover how Vestas leads wind energy innovation with 3D printing, reducing costs, saving time, and boosting efficiency with Markforged technology.

Read MoreFarason's Custom Mechanical Gripper with Markforged 3D Printing

Discover how Farason Corporation enhanced automation with Markforged 3D printing, creating lightweight, durable grippers with custom features for robotics solutions.

Read MoreIntroducing Nylon White FS: Expanding 3D Printing for Food and Beverage Factory Floors

Discover Nylon White FS, a food-safe 3D printing material certified for food and beverage manufacturing. Boost efficiency while ensuring compliance.

Read MoreTransforming End-of-Line Automation with 3D Printing at TMG Impianti: Case Study

TMG Impianti adopted Markforged 3D printing to boost efficiency, reduce lead times, and create lightweight, complex components for end-of-line automation.

Read MoreHow BMF GmbH uses Digital Source

Discover how BMF GmbH uses Markforged Digital Source to reduce machine downtime, ensuring quick, on-demand part replacements and enhanced operational efficiency.

Read MoreMeet the FX10: The First Industrial Metal and Composite 3D Printer

Discover the FX10, Markforged's latest 3D printer combining metal and composite printing, boosting manufacturing efficiency and versatility.

Read MoreBoosting Efficiency for Packaging Machine Builders with Tailored Additive Manufacturing Solutions

Discover how custom 3D printing solutions improve packaging machines, cut costs, and speed up production for the food and beverage industry.

Read MoreForging a Promising Future through Vocational Training

Discover how Goierri Eskola excels in vocational training through innovative additive manufacturing projects and community collaboration.

Read MoreThe Role of Robotics in the Food Industry

Discover how robotics and automation are addressing workforce, safety, and efficiency challenges in the food industry while enhancing adaptability.

Read MoreDixie Iron Works Innovates with 3D Printing for Cost Savings

Discover how Dixie Iron Works uses 3D printing to reduce costs and enhance product innovation in the oil and gas industry.

Read MoreSQP Engineering and Strada Percussion Drilling Systems

SQP Engineering and Strada Percussion used Markforged's FX20™ and Onyx® to 3D print precision calipers, cutting tooling costs by 30% and lead time from 2 weeks to 2 days.

Read MoreGet Parts Faster with Mark Two and Onyx Pro Turbo Print

Double your print speed with Mark Two and Onyx Pro Turbo Print. Get parts delivered faster, improving productivity and ROI.

Read MoreFesto uses Markforged 3D printers for manufacturing electronic components

Explore how Festo leverages Markforged 3D printers at their Scharnhausen plant to enhance electronic component manufacturing. Discover cost savings and operational benefits.

Read MoreBODUK Co. Ltd. : Innovating Industrial Drone Inspections with 3D Printing Technology

Explore how BODUK Co. Ltd. has enhanced its industrial drone manufacturing operations. Utilizing Markforged, BODUK has achieved a significant reduction in production times.

Read MoreDeveloping and Designing Vacuum Grippers for Production Line Robots

Discover how Harvestance designs lightweight, strong vacuum grippers for production line robots, reducing weight and boosting efficiency.

Read MoreDiscover How Vogel Druck Saved Big with Markforged

Vogel Druck enhanced its printing services by incorporating Markforged's Mark Two 3D printers, enabling the swift production of spare parts and reducing operational costs. This strategic move demonstrates the company's proactive approach to leveraging additive manufacturing for greater efficiency and cost savings.

Read MoreThe Critical Role of 3D Printing in Food and Beverage Production

Food and beverage industry leaders keep lines running with on-demand MRO parts and production tooling. Improving throughput, optimizing line changeovers, and ensuring operator safety are crucial to the growing adoption of factory automation. The Digital Forge offers manufacturers a simple way to build custom parts in hours instead of days, print replacement parts for aging equipment no longer easily serviced by an OEM, and lightweight robotic arms to improve automation equipment performance.

Read MoreTransforming the Meat Processing Industry with Additive Manufacturing

Learn how additive manufacturing is reducing downtime and costs in the meat processing industry. Discover how innovative solutions are transforming operations.

Read MorePTI Tech - Advancing the process of MIM prototyping with metal binder jetting.

PTI Tech revolutionizes MIM prototyping with Markforged metal binder jetting, slashing development time/cost for elevator buttons, and bypassing traditional tooling.

Read MoreCodeval Aluminum's Journey with 3D Printing

Codeval Aluminum SL transforms architectural innovation with the Mark Two 3D printer, saving time and costs. Explore their use of TPU and plans for the Metal X™ system in stainless steel components.

Read MoreThe U.S. Department of Veterans Affairs (VA)

Transforming lives with innovative assistive technology solutions. Discover how the Central Virginia VA Health Care System utilizes Smooth TPU 95A for customized designs, enhancing patient care.

Read MoreKST Moschkau: Using FX20 for Low-Volume Production

Learn how KST Moschkau optimized their low-volume production using Markforged FX20, slashing lead times and costs while ensuring top-notch quality.

Read MoreHow to Define Precision in 3D Printing, Factors that Affect Precision, and Possible Trade-offs.

Discover 3D printing precision, covering factors like resolution and calibration. Make informed decisions with a concise guide on selecting the right 3D printer for your needs.

Read MoreHawaya Racing's Innovation Journey with Markforged X7

Learn how Hawaya Racing's Markforged X7™ adoption transformed Harley-Davidson drag racing, cutting costs and enhancing performance for a winning edge.

Read MoreEnd-of-Arm Tooling and 3D Printing in Industrial Automation.

Explore the game-changing impact of 3D printing on End-of-Arm Tooling (EOAT). Discover real-world examples and how Markforged technology accelerates efficiency, cuts costs, and boosts strength in industrial automation.

Read MoreSonic Communications - Case Study

Sonic Communications can now go from design to final product four times faster with Markforged 3D printing than they would using in-house machining.

Read MoreSiemens Energy Technology Application Center - Case Study

Explore Siemens Energy TAC's success using Markforged Simulation for efficient gas turbine fixture design and rapid iteration of 3D-printed robot arm backpacks. Revolutionizing structural analysis and additive manufacturing.

Read MoreMarkforged Introduces FX10 the most versatile Industrial 3D Printer

Discover the new Markforged 3D Printer FX10, which redefines on-demand manufacturing with its compactness and efficiency. Partner with Chemtron Pte Ltd for top 3D printing solutions in Southeast Asia.

Read MoreA Success Story of Manufactura Moderna de Metales's Additive Manufacturing Journey

Discover how MMM's innovative approach to Additive Manufacturing transformed their automotive component production, slashing delivery times and achieving precision.

Read MoreHarnessing Additive Manufacturing: Invest More to Tackle Supply Chain Challenges

Discover how 3D printing technology can revolutionize supply chains, reduce disruptions, and enhance efficiency. Explore key findings and the role of companies like Chemtron Pte Ltd in advancing additive manufacturing solutions.

Read MoreRevolutionizing the Future of 3D Printing: Markforged 3D Printers

Explore Markforged's game-changing 3D printers in Southeast Asia, offering unmatched strength, efficiency, and precision. From Desktop to Metal Series, find your ideal 3D printing solution with Chemtron Pte Ltd and stay ahead in the modern industry.

Read MoreUsing Markforged Simulation to Enhance Efficiency in Engine Development: PUNCH Torino case study

Discover how PUNCH Torino used Markforged Simulation to reduce development time by over 50%, optimize 3D-printed tool designs, and enhance efficiency in engine development and 3D printing processes.

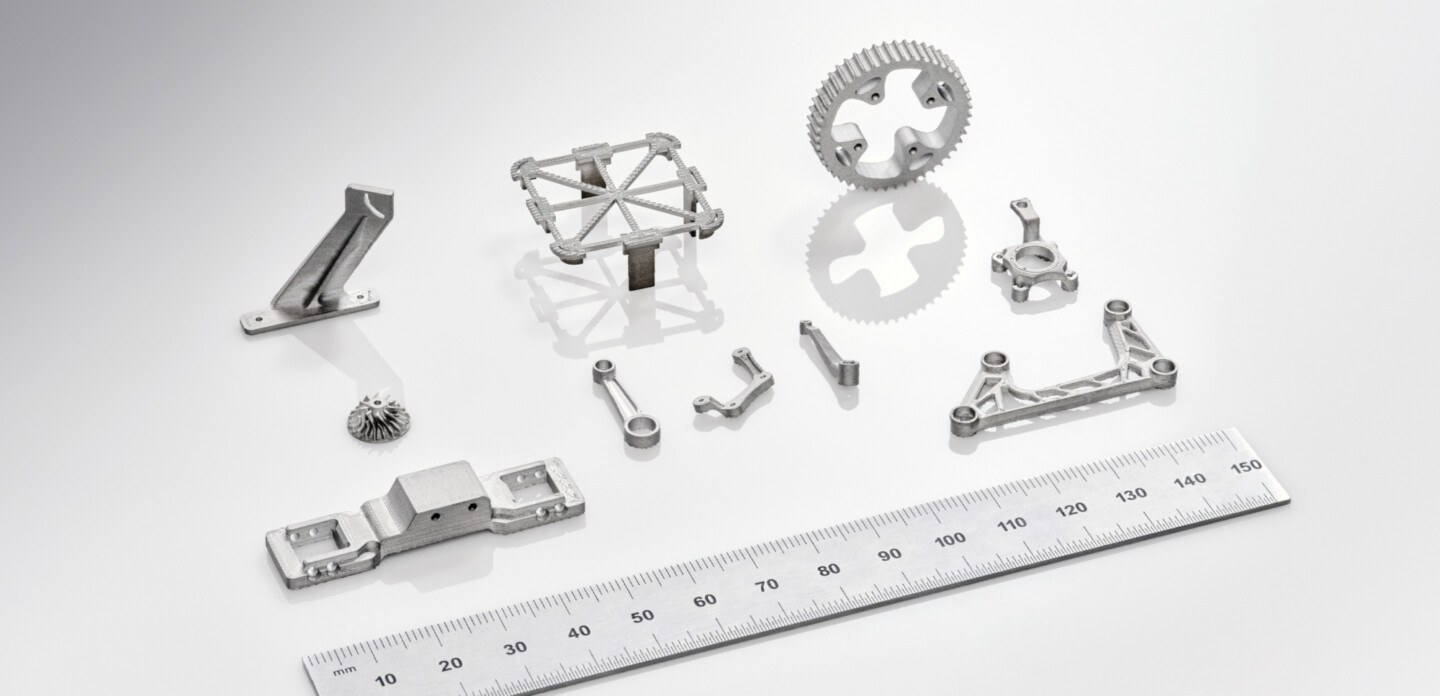

Read MoreMarkforged Introduces Fine Features For 17-4PH Stainless Steel on Metal X System

Markforged introduces new print modes for 17-4PH Stainless Steel on the Metal X. Print fine features in high resolution, or accelerate speed without sacrificing quality.

Read MoreUtilizing carbon fiber reinforcement for better cost and speed

Witness the remarkable transformation of McService by utilizing carbon fiber reinforcement – a strategic move that accelerated production and maximized cost-efficiency.

Read MoreFuture of EDM Machining with 3D Printed Copper Electrode

Read about the remarkable innovation from the University of Las Palmas de Gran Canaria's Research team - a cutting-edge 3D printed Copper EDM electrode.

Read MoreInnovative 3D Printed Tools: A Solution for Jeep Enthusiasts

Discover how this Jeep enthusiast designed 3D-printed tools to make his Jeep Wrangler's roof panels and doors easier to remove. Here's a look at his entrepreneurial story.

Read MoreMaximizing Supply Chain Resilience: Embracing Additive Manufacturing for Flexibility

Discover how additive manufacturing revolutionizes supply chain management. Overcome limitations and build resilience by producing essential components on-demand.

Read MoreSolving Manufacturing Problems With Markforged | SQP Engineering

Discover how SQP transformed their manufacturing processes with Markforged to accelerate production, improve product performance, and reduce costs.

Read MoreZero Tolerance LLC - Improving Productivity With Markforged 3d printers

Learn how Zero Tolerance LLC, reduced overall cycle times by 19-20 seconds and increased production by 50% using Markforged 3D printers.

Read MoreClenaware Systems: Transforming Manufacturing with Markforged

Discover how Clenaware transformed their manufacturing process, achieved cost savings, improved production times, and enhanced their product quality using Markforged.

Read MoreUnleashing the Power of Additive Manufacturing with Digital Forge

Explore Markforged's Digital Forge, an advanced additive manufacturing platform that offers reliable and cost-effective solutions for producing high-quality parts.

Read MoreMarkforged Introduces Fine Features For Pure Copper On Metal X

Now use your Metal X System for an even wide range of application with the new Fine Feature Print setting for pure Copper. No hardware change required.

Read More3D Printing Electric Vehicle Busbar Prototypes In Pure Copper

As the automotive industry continues the shift towards electric vehicles, 3D printing electroconductive parts on the Metal X system offers a key to address...

Read MoreMetal 3D Printing - A Comprehensive Guide To Different Technologies

Read this blog post to learn about the three leading types of 3D metal printer technologies — metal FFF (Fused Filament Fabrication), powder bed fusion, and binder jetting...

Read MoreTodema - Reducing Time And Cost By 80% Using Markforged 3D Printers

Producing customized machinery for its customers while remaining at the cutting-edge of innovation has always driven Todema to create a large number of prototypes...

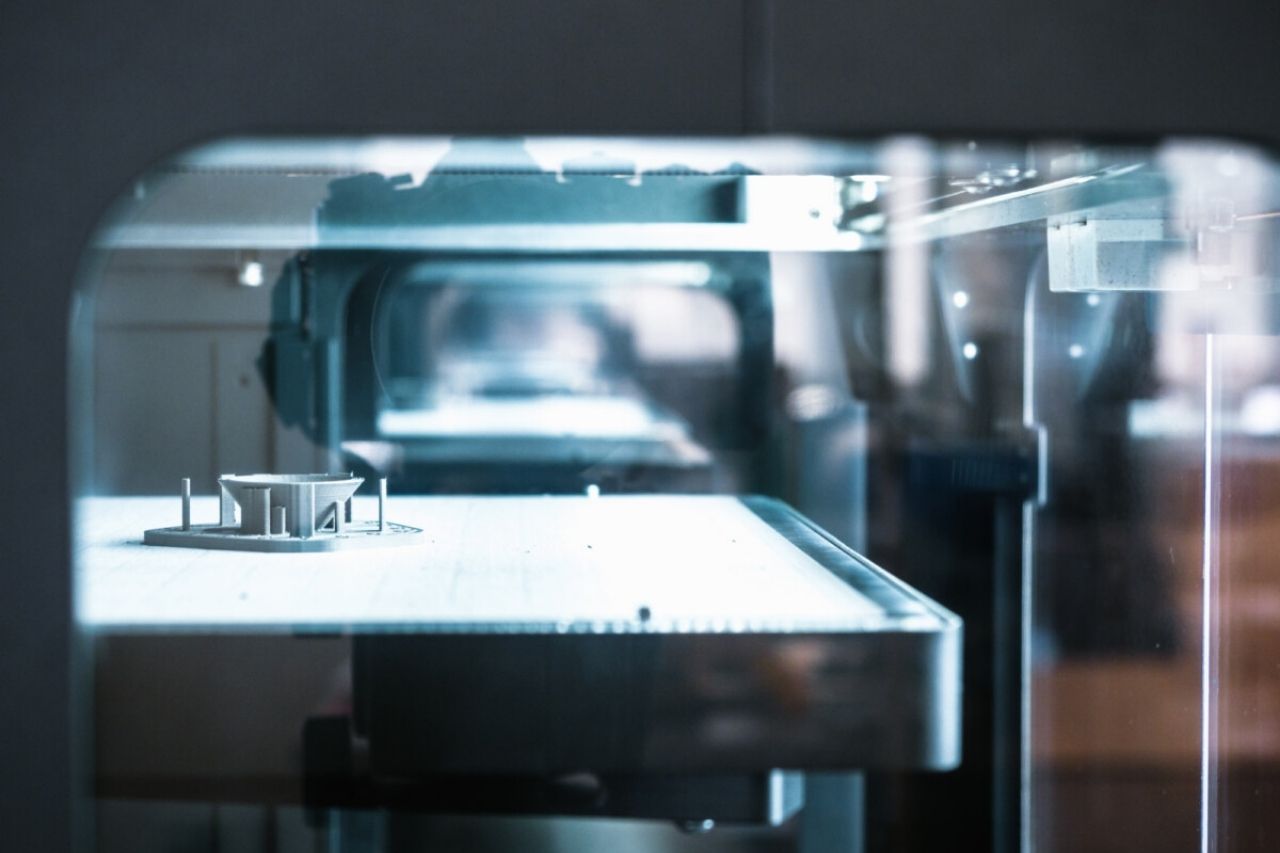

Read MoreRapid Prototyping With 3D Printing. How to improve your manufacturing process?

Rapid Prototyping is the use of digital technologies to design and fabricate prototypes faster and easier. Rapid prototyping typically relies on 3D printing technologies...

Read MoreWhat Is Additive Manufacturing? Understanding The Technology And Its Impact.

Within the industry, additive manufacturing and 3D printing are typically used interchangeably. Technically speaking, however, 3D printing is a subset of AM, which includes...

Read MoreHow 3D Printed Tools & Fixtures are Revolutionizing Manufacturing?

Learn how manufacturers around the world are utilizing 3D printing for tooling and fixtures to reduce cost while accelerating the time to market new products...

Read MoreWhat Can You Do with Metal 3D Printing?

From tooling inserts with cooling channels to lightweight structures for aerospace, any application that involves complex metal parts potentially benefits from metal 3D printing.

Read MoreAdditive Manufacturing in 2022

2022 marks the start of a new wave of changes and advances in the field of additive manufacturing that will redefine the wider manufacturing sector, helping it address some of its longest standing challenges

Read MoreFactories Of The Future Powered By Large Format 3D Printers

The large-format industrial 3D printer not only unlocks familiar applications on a larger scale but opens up a range of new uses and benefits for production-ready environments.

Read MoreHobbyist vs Professional 3D Printer

From futuristic concepts to creative hobbies to the new industrial revolution, 3D printing is a current and valuable technology in the manufacturing and design arena. 3D Printing often conjures up the image of a

Read MoreBenefits of Adopting 3D Metal Printing

Metal 3D printing has changed the landscape of manufacturing. This technology has opened up a range of possibilities for manufacturers. The technology could help to drive new product development strategies by enabling economical low-volume and on-demand production, innovative design possibilities, and of course, mass customization.

Read More5 Supply Chain Makeovers Powered by 3D Printing

Talk to any manufacturer, and you will hear the same story, I can't get my part to make my products, or my product is stuck at the port, and I have no idea when to expect it. For the global manufacturers, supply chain issues present the biggest threat to productivity

Read MoreReplacing Aluminum Parts With 3D Printed Carbon Fiber

Recently, countries around the world are facing a major shortage of aluminum that began at the start of the pandemic, which has led to steep price increases in aluminum. Since January 2021, aluminum prices have shot up by over 50%

Read More