Revival Electric Vehicles: Pioneering Classic Car Electrification

The Customer

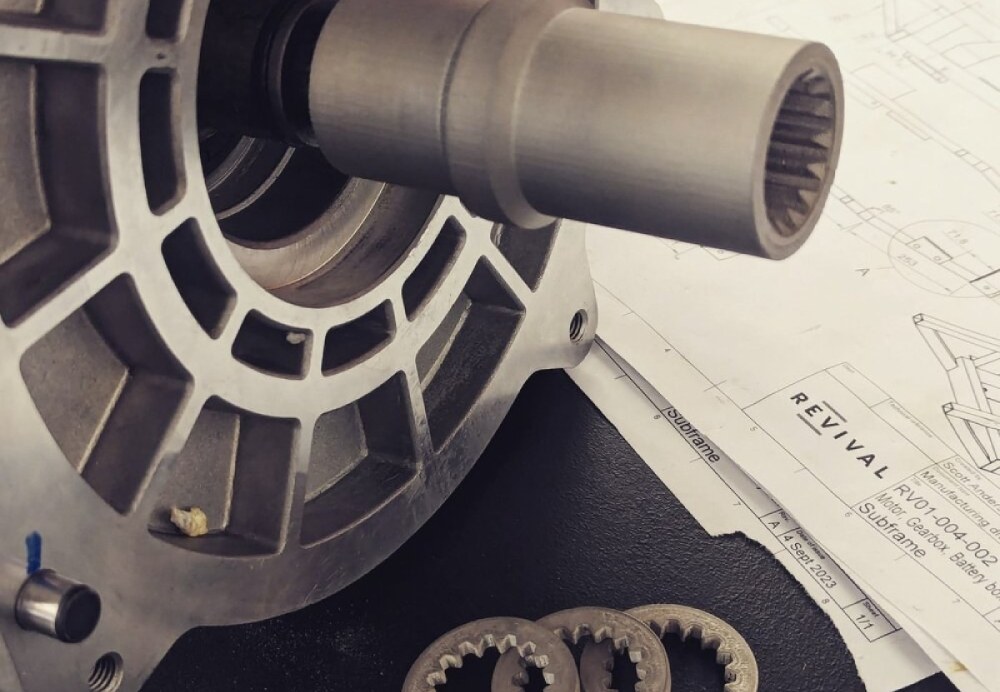

Revival Electric Vehicles, an automotive engineering firm based in Melbourne, is creating modular components that allow for the replacement of a vehicle’s petrol engine with an all-electric drivetrain and battery modules. Currently, they are converting a 1972 BMW 2002, which will serve as their proof of concept. This project aims to help them begin marketing conversion kits before the end of 2024.

Manufacturing issues emerged due to the complexity and precise tolerances required for the spline shaft adapter that connects the new motor and gearbox. As a result, Revival sought assistance from Bremar, a specialized engineering design company.

The Challenge

Scott Anderson, the managing director of Revival, mentioned that he had previously collaborated with Bremar during the initial design phase. Bremar had assisted in scanning the vehicle for 3D CAD work, which made Anderson aware of their investment in a range of industrial 3D printers. These printers include the Mark Two™, X7™, FX20™, and Metal X™, all supplied by the industry leader, Markforged.

“I completed the initial design for the adapter and we printed it a few times in PLA to get a feel for the finished item. After discussions with Bremar, they printed test parts to ensure the tolerancing would be right before producing the finished component. Thin tolerance tests for both ends of the adapter ensured that the final unit worked first time.” – Scott Anderson, Managing Director, Revival Electric Vehicles

Revival initially explored conventional methods like broach milling or electrical discharge machining to produce the adapter. However, they were discouraged by the potentially long lead times and the estimated cost of $1,500 for a one-off unit.

The Solution

“Working with Bremar, we were able to go from initial design to final unit in just a few weeks, much of which was taken up with finding the time to drop the motor and gearbox off for tolerance fit testing, so the time actually spent on the process itself was probably as little as a week, and the cost was less than a half of what we’d have paid going the conventional route,” he said.

Revival's confidence in Bremar's expertise, along with the utilization of Markforged's advanced 3D printing solutions, greatly streamlined the manufacturing process. This approach allowed for rapid iterations, easy testing of fitments, and the ability to finalize designs without the limitations of traditional machining. As a result, both time and costs were significantly reduced.

The Future

“We’re confident the finished adapter, printed in 17-4 PH Stainless Steel, will outlast both the motor and the gearbox, and we’re happy to use other 3D printed parts in our builds as we feel they are a great solution for rapid prototyping and testing and are particularly well suited for small scale production,” said Scott.

Revival Electric Vehicles plans to enhance its conversion kits by utilizing additive manufacturing for additional components. This approach will ensure high precision, cost-effectiveness, and shorter production times. With the support of Markforged’s technology and expert partners like Bremar, the company is well-positioned to transform classic car electrification through innovative engineering and digital manufacturing.

The Conclusion

Organizations aiming to adopt next-generation technologies can take inspiration from Revival Electric Vehicles' use of Markforged 3D printing equipment, which exemplifies the transformative potential of additive manufacturing. These technologies significantly enhance manufacturing efficiency and reduce lead times. With the support of Chemtron, a leading distributor in Asia, companies gain access to essential tools, training, and technical resources that facilitate a smooth transition to new technologies. By leveraging Chemtron's expertise alongside Markforged's capabilities, organizations can substantially improve productivity and sustainability.

Download the Free Report on How COVID-19 has Impacted Supply Chains

Gain key insights including: COVID-19 pandemic impact on business. 3D printing use during the health pandemic. Challenges facing manufacturers using incumbent technology. Future plans for investing in additive manufacturing. And more...

Get the eport