Revolutionizing Vinyl Playback: Wilson Benesch's Innovation Journey

The consumption of music today is primarily dominated by digital streaming. Other physical music formats, such as cassette tapes, mini-discs, DVD-Audio, and compact discs, have largely fallen out of the mainstream. However, vinyl records, which predate all of these formats, continue to thrive, with sales experiencing an increase of nearly 30% in 2020.

Design Innovation with Carbon Fiber

Wilson Benesch is a British family-owned brand specializing in high-tech audio products. Since its first product, a carbon fiber turntable launched in 1989, the company has focused on innovative design and performance. Today, it integrates carbon fiber technologies into all its products, setting industry-leading performance standards.

Craig Milnes, co-owner and Design Director of Wilson Benesch, stated: "Many consumers might consider the use of carbon fiber and take it really only at face value, indeed the material is now commonly seen as a surface finish in consumer products to distill the idea of a given product as being ‘high-tech’. The difference with Wilson Benesch is that we are innovating complex hybridized structures that use carbon fiber which by some considerable margin outperform similar structures that we could create using other materials. Thus we are deriving a significant performance advantage over our competitors."

Christina Milnes, co-owner and Managing Director at Wilson Benesch added: “In 2021, innovative product design is more important than ever. Consumers today are highly knowledgeable, passionate and they are linked to and know a brand and its products now more intimately than ever before. We recognize that in this respect, we offer something genuinely unique and authentic.”

Wilson Benesch enhances its advanced materials technology by utilizing state-of-the-art manufacturing systems. These systems include a CNC Machine Suite and a Carbon Fiber Composite Suite, allowing the company to produce 90% of its components in-house. To drive innovation, Wilson Benesch is actively pursuing cutting-edge manufacturing technologies for its latest product developments, with the goal of pushing the boundaries of design and performance.

Collaborating with Markforged

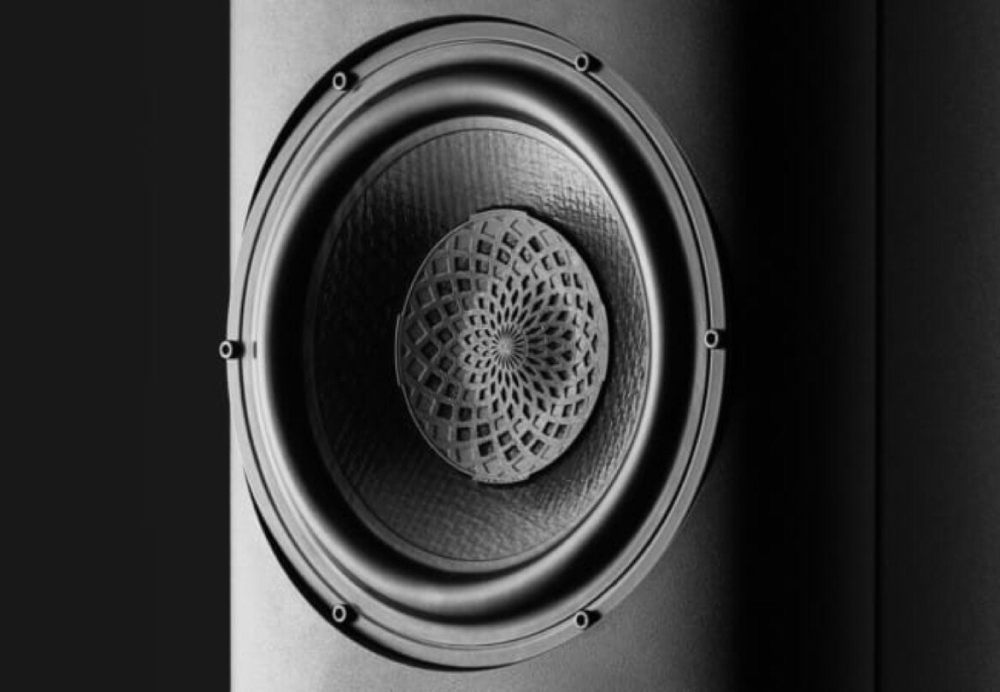

Wilson Benesch's upcoming GMT ONE System™ turntable, scheduled for launch in 2022, showcases the company's commitment to innovation. This product is the result of a decade-long development process and utilizes Markforged's additive manufacturing technologies. The Markforged platform combines design flexibility with advanced material science, enabling Wilson Benesch to create optimized and complex components that were previously unattainable through traditional manufacturing methods.

Markforged's Digital Forge platform allows Wilson Benesch to produce high-performance 3D components, including lightweight, carbon fiber-reinforced structures with maximum stiffness and optimal energy damping.

Craig Milnes emphasized the significant impact of this partnership, stating, “Some of our new products would not exist without Markforged. The GMT ONE System is the most ambitious product development effort by Wilson Benesch. Markforged allows us to create advanced, high-performance components quickly, helping us bring products to market faster. What previously took over a week to machine from metal can now be produced from carbon-doped nylon in just a few hours.”

The Conclusion

Wilson Benesch is incorporating advanced technology into its operations through Markforged 3D printing machines, highlighting the transformative impact of additive manufacturing on production. These technologies enhance efficiency, reduce lead times, and facilitate the creation of high-performance components.

By partnering with Chemtron, a leading distributor in Asia, organizations can access essential tools, training, and technical expertise for effective integration. Leveraging Chemtron's insights alongside Markforged capabilities allows your organization to improve design, production, and overall product quality significantly.

Download the Free Report on How COVID-19 has Impacted Supply Chains

Gain key insights including: COVID-19 pandemic impact on business. 3D printing use during the health pandemic. Challenges facing manufacturers using incumbent technology. Future plans for investing in additive manufacturing. And more...

Get the eport